Where Precision Meets Prediction

Welcome to P2MS, your trusted partner in predictive and precision maintenance solutions. We specialise in dynamic in-situ balancing, shaft-to-shaft laser alignment, vibration analysis, thermographic inspections, and oil sampling & tribology - all designed to extend the life of your assets, reduce downtime, and enhance operational efficiency. Whether you need targeted precision maintenance or a fully customised condition monitoring program, we provide reliable, data-driven insights to keep your machinery operating at peak performance. Backed by hands-on expertise and a commitment to excellence, P2MS is here to support your maintenance strategy every step of the way.

P2MS - Precision & Predictive Maintenance Services is committed to delivering top-notch reliability engineering and condition monitoring services.

Dynamic in-situ rotor and fan balancing is a process performed directly on installed equipment, eliminating the need for disassembly and minimising downtime. It ensures accurate balancing by reflecting actual operating conditions, making it highly effective for industrial maintenance. The process involves measuring vibration levels and phase angles using a tachometer and vibration analyser to identify unbalance in rotating components. Correction weights are then added or removed from the rotating elements to reduce imbalance forces and restore smooth operation.

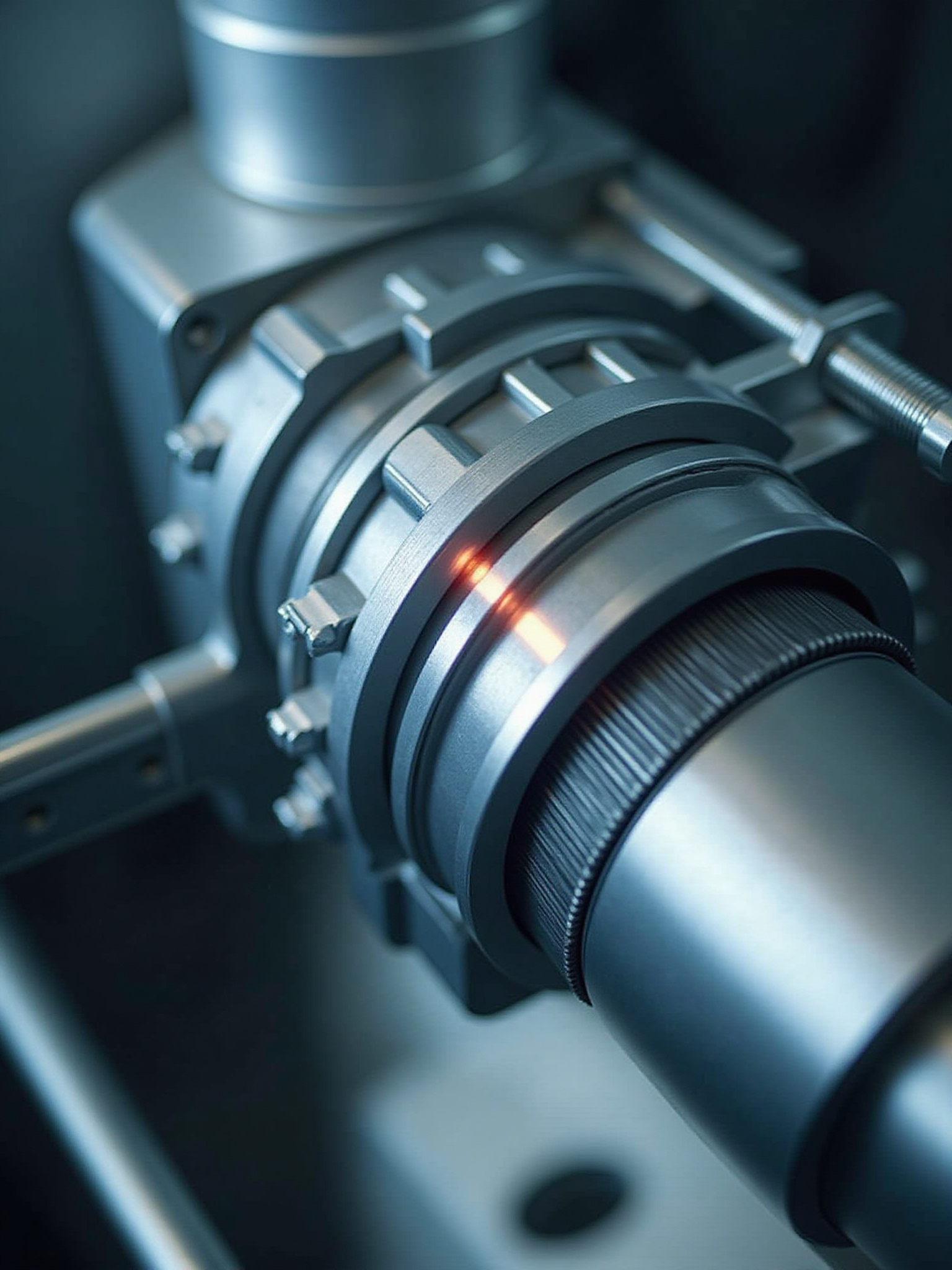

Shaft-to-shaft laser alignment is a precise method used to ensure that two rotating shafts are correctly aligned within their respective ISO specifications along their axis. Misalignment can lead to excessive vibration, premature wear, and mechanical failure. Laser alignment systems utilise a laser beam and sensors mounted on each shaft to measure angular and offset misalignment in real time. These systems provide accurate, digital feedback to guide alignment adjustments, ultimately improving machine efficiency, extending equipment life, and reducing maintenance costs.

Vibration analysis. At P2MS, we utilise vibration analysis as a predictive maintenance technique to assess the health of rotating machinery by measuring and analysing vibration levels. The collected data is typically processed using tools such as Fast Fourier Transform (FFT) to identify specific frequency patterns that reveal underlying mechanical issues, enabling early intervention and minimising unplanned downtime. Whether you require a simple factory acceptance test for reconditioned machinery or tailored vibration surveys conducted regularly to suit your maintenance budget and operational needs, P2MS is ready to accommodate you.

Thermography, or thermal imaging, is a non-contact maintenance technique used to detect heat anomalies in electrical components within control panels or distribution boxes. By using a thermal imaging camera, technicians can identify overheating connections, overloaded circuits, faulty breakers, or loose terminals before they lead to equipment failure or fire hazards. Hotspots appear as elevated temperatures on the camera display, allowing early diagnosis and targeted maintenance without the need to shut down systems. This proactive approach improves safety, reduces downtime, and ensures the reliability of critical electrical infrastructure.

Oil sampling and tribology are essential practices in condition-based maintenance used to monitor the health of lubricated machinery. Oil sampling involves extracting a small, representative sample of lubricant from equipment such as gearboxes, engines, or hydraulic systems, which is then analysed to determine properties like viscosity, contamination, wear particles, and additive degradation. The interpretation of these results, grounded in the principles of tribology, provides a deeper understanding of component condition and lubricant performance. This enables early detection of potential failures, reduces unplanned downtime, and helps extend machinery life.